This pattern card illustrates the Dycrofix 'P' dyes from JAGSON which are suitable for printing of cellulosic fibers.

1. Pretreatement of the goods

To ensure optimum results in reactive printing of woven or knitted fabric all impurities in the fibre, lubricants, auxiliaries and processing chemicals that could react with reactive dyes or adversely affect the printing process must be removed to obtain maximum colour yield brilliancy levelness and wet fastness properties on cotton, it has been mercerized or treated with a caustic soda solution of at least 22 °Be (16.4%) Regenerated Cellulosic fibres should be treated in a tensionless state with a caustic soda solution of approx 6-8 °Be (4-5%) Alkaline pretreatment improves further dimensional stability and facilitates washing-off of the prints.

2. Print paste preparation

Most important ingredient is the thickener

Sodium alginate is the ideal thickener for the purpose, which does not react with the dyestuff and can be very easily washed off

Print recipe

A. Stock Thickener

| Sodium alginate thickener | 400-600 Parts |

| Urea | 100-200 Parts |

| Dycrogol (Resist Salt) | 10 Parts |

| KBI Liquid | 5 Parts |

| Sodium Bicarbonate | 25-30 Parts |

| Preservative | 0.5-1.0 Parts |

| Water | X Parts |

| 1000 Parts |

B. Print paste Preparation

| Stock thickener | X Parts |

| Dycrofix 'P' Dyes | Y Parts |

| 1000 Parts |

3. Fixation

The following fixation methods can be used as per availability of equipment:

| Fixation medium for one-phase printing | Substrate | Time min | Temperature | Alkali |

|---|---|---|---|---|

| Saturated steam | WO/silk | 10-20 | 102℃ | Sodium Acetate |

| Saturated steam | CO,CV | 8-12 | 102 DC | Sodium Bicarbonate or Soda Ash |

| Hot Air* | CO | 5 | 150℃ | Sodium Bicarbonate or Soda Ash |

| Hot Air* | PES/CO | 1 | 190-200 C | Sodium Bicarbonate or Soda Ash |

| Superheated steam* | PES/CO | 6-8 | 175 X | Sodium Bicarbonate or Soda Ash |

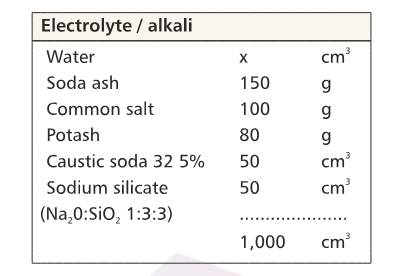

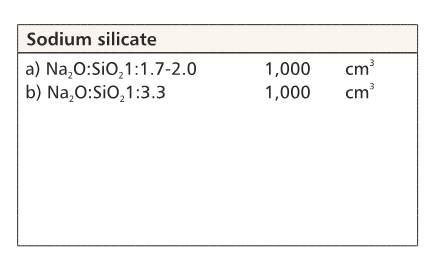

4. Two-phase prints

First of all the dried prints are impregnated open-width and crease-free with an alkaline fixation liquor and after that fixed as per the available equipment.

A horizontal padder with steel/rubber roller arrangement has effective to apply the alkaline fixation liquor which should allow both face padding and immersion of the fabric, depending on its structure and weight. The padding roller which comes into contact with the printed side of the fabnc should be mad of steel (S) and the nip roller should be covered with rubber(R)

Fixation Liquors:

Fixation medium : Superheated steam

Substrate : cotton, viscose

Time : 90sec

Temperature : 125℃

5. Washing-off

To obtain a clean white ground, high brilliancy and good fastness properties, carry out a proper washing-off process.

There are two stages for washing-off of prints. One is to remove thickeners, chemicals and unfixed dyes and another one is to maximize fastness properties

In first stage, to obtain a clean white ground, swell the dry thickening film and remove the swollen thickening, residual alkali, unfixed reactive dye and auxiliaries

The best results are achieved with a specific water flow, e.g. by spraying the goods with a low liquor level, effective separation of the rinse baths and rapid liquor exchange at 90-95℃. If this is not possible, we recommend starting the washing-off process worth cold water.

In two-phase methods, the swollen thickening, alkali, unfixed dye and auxiliary should be removed by spraying intensively at 40℃, preferably without standing liquor.

After this, the goods are washed first at 60-70℃ and then at 90-95℃.

The prints should be washed-off in soft water to prevent formation of sparingly soluble calcium alginate. It is important to washed-off all unfixed and hydrolysed dye components completely if it's still present in the woven or knitted fabric. As basically this is a diffusion process, the time/temperature relationship is important.

In the washing-off process, not too much trust should be placed in the action of any detergents used for water soluble dyes.

It is very important to ensure that the baths are close to the boil. As the temperature rises, the substantivity of hydrolysed dye declines and the rate of diffusion increases. This assists the removal of the hydrolysed dye from the fibre.

The information provided here is in good faith, as our current knowledge of the product without liability.