DYCROFIX

| Fastness | TestMethod | |

|---|---|---|

| Light ISO 105-B02 |

Shade Changes Blue scale (1-8grade) |

Upper - 1/1 SD, Lower - 1/10 SD NB, Bk : Upper -2/1 SD, Lower -1/1 SD |

| Washing ISo 105 C06-C25 |

Upper - Shade change Lower - Staining on cotton |

4g/l ECE reference detergent, 1g/l Sodium perborate 30min. at60℃ |

| Chlorinated water ISO 105-E03 |

Shade change | 20mg/l Active chlorine at pH 7.5, Liquor ratio 100:1 Treat for 1hr at 27℃ |

| Perspirtion ISO 105-E04 |

Upper - Shade change Lower - Staining on cotton |

Acid solution - 0.5g/l L-histidine, 5g/l NaCl 2.2g/l NaH2PO42H2O, pH5.5, 4hrs at 37℃ Acid solution- 0.5g/l L-histidine, 5g/l NaCl 2.5g/l Na2HPO42H2O, pH 8.0, 4hrs at 37℃ |

| Perspiration-light ISO 105-B07 |

Upper - Acid perspiration ,br> Lower - Alkali perspiration | Perspiration fastness - ISO 105-E04 Light fastness - ISO 105-B02 |

| Bleaching DIN 54034 ISO 105-N02 |

Shade change | 0.5g/l Active chlorine, pH11.0 by adding 10g Sodium carbonate, Liquor ration 50:1 5.0ml/l H2O2(30%), 5ml/l Sodium Silicate 0.1g/l Magnesium chloride, pH 10.5, 1hr at 90℃ |

| Rubbing ISO 105-X12 |

Staining on cotton | Upper - Dry Lower - Wet |

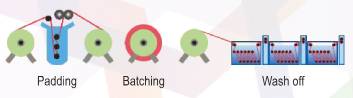

Cold pd-batch dyeing

Sodium silicate / Caustic soda

Dyeing depth

Pale, Medium, Dark

Padding Temp.

20-30℃ (high pad liquor stability at 20-25℃)

Batching time

8-16 hours

Liquor pick up

Cotton 60-70%, Viscose rayon 70-80%

Metering pump

Reqired

Pad liquor

Dyes X g/l

Penetration agent 1-2 g/l

(with wetting agent)

Sodium silicate 37-40°Be 70 ml/l

Caustic soda 36°Be 10-30 ml/l

Required amount of alkali

| Dyestuff | g/l | <10 | 20 | 30 | 40 | 50 | 60 | >70 |

| Sodium silicate (37-40°Be) | ml/l | - | - | - | 40 | - | - | - |

| Caustic soda (36°) | ml/l | 10 | 15 | 20 | 25 | 28 | 30 | 30 |

Notes

- This method is the standard procedure for liquor temperature of 20-30℃.

- Short fixation time

- Metering pump required

- Good bath stability

- Atmospheric carbon dioxide has almost no effect during storage.

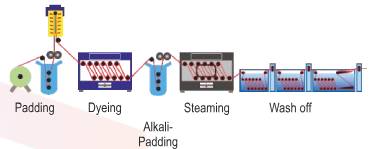

Continuous dyeing

Pad-Dry-Pad-Steam (PDPS)

Pad liquour

Dyes X g/l

Wetting agent 1-2 g/l

Reduction protectant 1-3 ml/l

Migration inhibitor 5-10 ml/l

Pad liquour temp

20-30℃

Liquor pick up

60-80%

I.R. pre-drying

To a residual moisture content of

30-35%

Drying

Dry at 110-120℃

Chemical Liquor pick up

70-80%

Steaming

60-90sec. in saturated steam

(101 105℃)

Required amount of salt and alkali

| Dyestuff | g/l | <10 | 10-30 | >30 |

| Salt | g/l | 200 | 250 | 250 |

| Soda ash | g/l | 20 | 20 | 20 |

| Caustic soda 36℃Be | ml/l | 8 | 12 | 15 |

Notes

- High productivity and colour yield

- Good appearance

- Classic procedure for continuous dyeing of woven fabric

- When using dyes with low reactivity such as Dycrofix Turquoise Blue G the amount of caustic soda should be raised by 30%

- if the goods are stored, after drying but before fixation, they should be wrapped in and opaque material to protect them from daylight.

Auxiliaries

Sequestering agents

Sequestering agents are used to soften water and bond free heavy metal ions. Sequestering agents that do not remove the metals from reactive metal complex dyes should be used, as otherwise the shad can change and fastness propertoes can be impaired. Therefore EDTA-based products are not suitable.

Antofoams

Foam can impair the running of the goods in bath and thus reduce levelness. Extremely dilute solutions should be dosed into the liquor slowly. Silicone-free antofoams should be used where possible.

Lubricant

Lubricant agent prevents crack marks and creases, it should have no adverse effect on dye liquor stability.

Alkali & Salt Recommendation